Moog has integrated its next-generation slip ring with a fiber optic rotary joint (FORJ) as a replacement for the carbon-brush slip rings that control the blade pitch on 2.5 MW and higher GE turbines.

Existing carbon-brush slip rings in many GE wind turbines create dust that disrupts power and communications, says the company, adding that it has designed its new slip rings as a “set it and forget it” product from the outset due to its fiber brush technology.

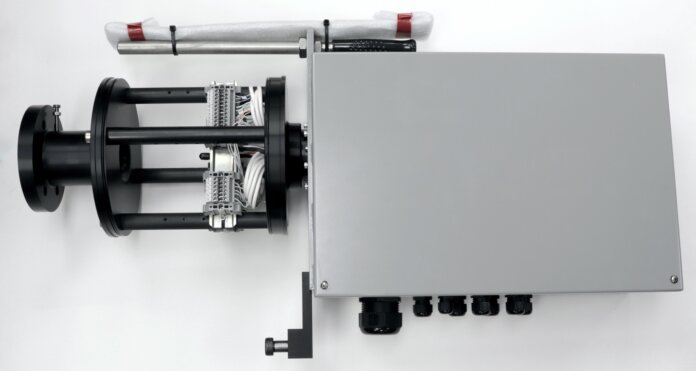

The company’s latest version, model WP7286-5N, seeks to incorporate a smaller footprint and weigh less than competing designs. Additionally, model FO286b transfers data via fiber optic output.

“Moog’s new offering for 2.5 MW and higher GE turbines leverages our success providing more than 10,000 high-reliability pitch slip rings for GE turbines as well as thousands of FORJs into the wind energy market,” says Moog’s Larry Bryant.

“We have a long track record of supplying rotary interfaces, and this new slip ring-FORJ integration represents an enhanced iteration of our proven offering. Moog’s experts designed our FORJ based on years of testing and delivering similar systems for the global wind market.”