An Oregon start-up is developing a new wind turbine foundation system that it says could cut the amount of concrete used by 75%.

RUTE Foundation Systems and a research team at Portland State University are receiving $66,000 in early-stage investment support from Oregon BEST – which funds and assists cleantech start-ups – to commercialize the new technology.

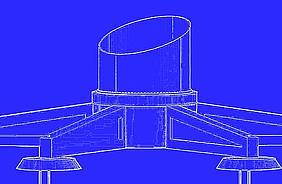

“We’ve developed a manufactured assembly of anchored grade beams that saves a lot of concrete, transportation costs, construction time and carbon dioxide,” says Doug Krause, founder of RUTE Foundation Systems. “Using this footing saves wind farm developers time and money, is more environmentally friendly, and reduces the cost of bringing renewable energy to the world.”

He explains that the RUTE foundation system is “delivered fully hardened” – in turn, bringing “very little risk as to if it will be installed, cured and ready when the turbine is delivered to the site.”

Krause uses an analogy of a massive Douglas fir tree held in place by a root system that weighs much less than the total weight of the tree.

Because the components in the system are made in a beam manufacturing plant, the finished product is three times stronger than cast-in-place concrete, says RUTE.

In addition, using less concrete requires less cement, which generates CO2 during production. In turn, the RUTE system can save as many as 6 million pounds of CO2 emissions for a single wind farm, Krause says.

The company is working with Franz Rad, a Portland State University (PSU) professor of civil and environmental engineering, to design instrumentation and procedures to monitor beam flexure in a range of soil and weather conditions. The work at PSU involves structural analysis, stress analysis, and design of the beams and the supporting hub. RUTE says the studies will provide critical validation of the material properties and structural design before initial field studies begin.

“It is interesting and challenging for me and my grad students to look at replacing massive concrete footings with a new foundation system that has post-tensioned beams connected to a hub,” says Rad. “Computer models show us the strength and stiffness of the foundation, and in the process, grad students learn about practical design, structural innovations and developing specifications for a field monitoring program.”

RUTE Foundations is also working with a technical team that includes Nishkian Dean Structural Engineers in Portland, Ore., and Marvel Bridge Engineers in Denver.