Olympus, a manufacturer of nondestructive testing (NDT) inspection equipment, is delivering new OmniScan X3 phased array flaw detectors with FMC/TFM to the University of Ultrasonics to support their advanced training courses.

The University of Ultrasonics trains inspectors who want to earn their certification in FMC/TFM to meet the American Society of Mechanical Engineers (ASME) requirements. Their advanced ultrasonic training, consulting and research and development experience helps them prepare technicians to use NDT technology, like the OmniScan X3 flaw detector, to perform critical inspections across industries, including wind power.

“We’re excited to provide the University of Ultrasonics with our OmniScan X3 flaw detectors to support their new FMC/TFM training classes,” says Dave Menne, vice president of industrial sales at Olympus.

“The University of Ultrasonics is a trainer that Olympus has supported for over 15 years. This relationship has been very good for the industry and inspectors since OmniScan flaw detectors are some of the most widely used PAUT instruments,” he adds.

Together, the University of Ultrasonics and Olympus are committed to providing current and prospective NDT technicians with leading-edge technology for a world-class FMC/TFM training program.

For more information about the collaboration, click here.

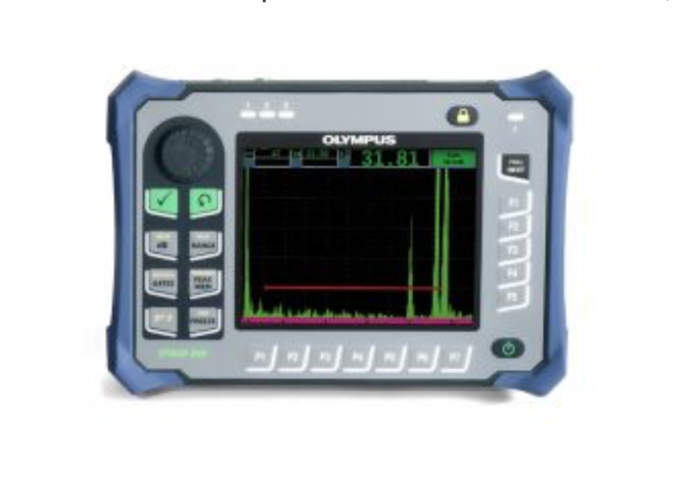

Photo: Olympus ultrasonic flaw detector