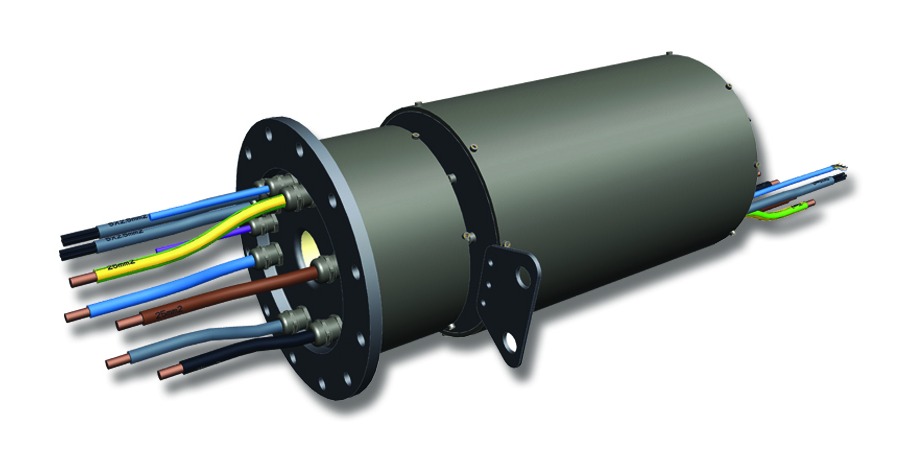

Moog Components Group Ltd., a division of Moog Inc. and a worldwide designer, manufacturer and integrator of precision control components and systems, has introduced a new pitch control slip ring specifically developed for the wind energy market.

According to Moog, the EPA3 slip ring is the next generation of advanced slip ring products that is well suited for both large and small wind turbines.

The company says that a key advantage of the Moog slip ring is its high-reliability, modular design that can be scaled and optimized for most requirements. Providing advanced Fiber On Tip contact technology, the slip ring extends the life of the product to reduce field maintenance at a lower cost of ownership. The new flexible design is easier to manufacture than conventional slip rings and decreases time to market.

The company notes that no maintenance is required.

Moog says the slip ring can be part of a large wind turbine electric pitch control system, with the option to integrate hydraulic pitch control systems if required. Further, it can also be used on the yaw axis of small wind turbines.

Speeds range from 0 rpm to 100 rpm, with through-bore model sizes up to 54 mm available, according to the company.

In addition to wind turbine applications, the new slip ring can also be used in industrial machinery and medical equipment.

Great to see manufacturers like Moog pushing further into the renewable space. I really feel like it’s the smaller, supporting technologies like this that are going to help renewable energies like wind reach their potential. Hell, we can’t have a renewable power revolution if the tech is failing every other day, right? I would be curious to see what the performance / maintenance on these is like compared to other solutions like wireless (https://powerbyproxi.com/2011/02/5-reasons-to-use-contactless-slip-rings/ ) – have there been any benchmarks carried out yet re: longevity and running costs? Curious to see these technologies go head ot head.