evoblade, a wind energy startup and spin-off of the Institute of Aerospace Technology (IAT) of the University of Applied Sciences Bremen, has developed a retrofittable spoiler for rotor blades – the EvoFlap – with the help of Deutsche Windtechnik and Wirtschaftsförderung Bremen.

“Rotor blades have a significant impact on the technical and economic performance of a wind turbine,” says Dr.-Ing. Frank Kortenstedde, founder and CEO of evoblade. “By developing and optimizing a retrofittable flow element, we wanted to achieve a technical and economic improvement in the properties of existing systems that leverages the advances in technical understanding.”

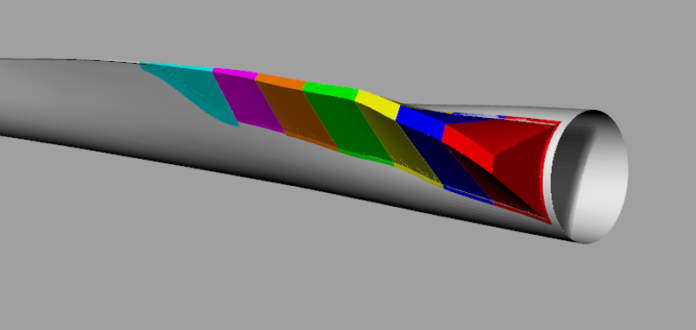

The EvoFlap can be adapted to different rotor blade types. The NEG Micon NM 82 turbine – with a rated output of 1.5 MW and a rotor blade length of 40 m – was selected as the basic system for the optimization. The flow element was developed using the GFRP sandwich technique and has an overall length of 10 m. It is divided into seven segments to allow assembly directly on an installed rotor blade.

To validate the annual energy output, ROMO Wind was commissioned to carry out independent performance monitoring using iSpin spinner anemometer technology. Measuring the wind speed in front of the turbine is advantageous – reference wind speed is measured directly and undisturbed. In addition to the test system, a second, adjacent turbine of the same type was equipped with iSpin technology as a reference system.

The results of the side-by-side study confirmed the increase in annual energy production (AEP) that had been predicted using simulated data. Recent results also show a 6% increase in AEP with an average annual wind speed of 7 m/s. In addition to increasing the yield, it was demonstrated that the EvoFlap also increases the bending and torsion strength of the rotor blade – having a positive effect on the service life of the blade.

The EvoFlap can theoretically be installed on all wind turbines that have a slender blade root design. The flow element is suitable as a retrofit solution – or for manufacturers – but needs to be adapted to the individual characteristics of the corresponding blade type.

Growing up, I frequently passed the Buffalo Ridge Wind Farm in southwestern Minnesota (USA). Given it was started in 1994 and into the late 90’s, they’ve now had a fair amount of re-building and upgrades. One environmental issue people complain about is the disposal of the blades. The article here mentioned increasing the lifespan of the blades – I’m curious if that would be useful enough to retrofit (really) old towers or if they’d still need a full rebuild. They’re now just burying blades in giant open-pit dumps (supposedly). Not shredding/recycling them. Curious what the lifecycle is for blades and… Read more »