DNV GL has launched a joint industry project (JIP) to develop a recommended practice intended to de-risk the adoption of “Twisties” and demonstrate the unitization of wind project cargo. The company defines “Twisties” as a modular project-cargo transport frame system that is sea-fastened using container twist locks.

According to DNV GL, the increasing size and quantities of wind turbines installed offshore means that a change in requirements is needed for shipping project cargo between manufacturing and marshalling port facilities and for feeding wind turbine installation vessels offshore.

The company says conventional feeder vessel operations have introduced many challenges, including operational limits on wave heights and wind speeds. However, DNV GL has identified that a fast feeder vessel using a RoRo (roll on, roll off) method of logistics transfer can avoid both wave limits and the tight wind speed limits often associated with lifting blades offshore.

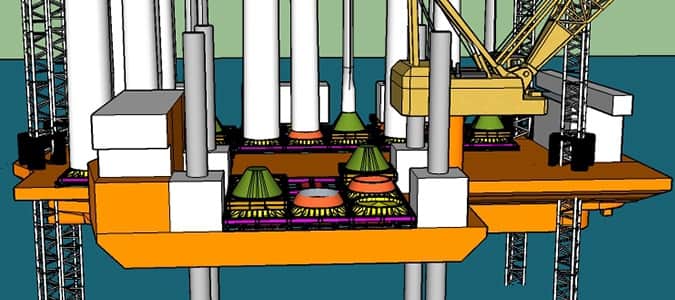

The constant requirement for handling project cargo of a repeatable form – with bolted flange connections – has sparked an industry desire to optimize and standardize transport logistics and sea-fastening arrangements, the company adds. Attempts at unitization have been, for example, grouping three blade sets into a unit. In addition, modular, twist-lock, stackable blade racks are now commonplace on the decks of installation vessels. DNV GL has taken this concept and proposed a unitization method that uses modular transportation and sea-fastening frames, based on standard, 20-foot, cargo container twist-lock centers.

According to DNV GL, transporting turbines and other wind farm components by using “Twisties” has shown to significantly decrease construction time to a single-season phase. It also allows for greater quantities of turbines to be installed by using a defined number of wind turbine installation vessels.

“Establishing a JIP will de-risk the implementation of this technology and promote the unitization of wind project cargo,” says Chris Garrett, senior offshore wind farms engineer for DNV GL. “This continues our commitment to reduce the cost of offshore wind, as outlined in DNV GL’s Offshore Wind Cost Reduction Manifesto. Understanding the technicalities of current wind industry transportation methods enables us to demonstrate the vast benefits that a standardized unit approach will bring to the entire industry.”