The Carbon Trust has launched a large trial of scanning light detection and ranging (LIDAR) technology in Dublin Bay, Ireland. This is the latest Offshore Wind Accelerator (OWA) project designed to help reduce the cost of energy from offshore wind.

Over the next three months, four different scanning LIDAR systems will be put through their paces, says Carbon Trust, alongside three vertical profiling LIDARs for validation purposes. Independent renewable energy company RES and maritime safety organization Commissioners of Irish Lights are supporting the project.

Accurate wind resource measurements are critical to wind farm development because they are used to calculate the potential energy yield from a wind farm, which dictates the terms of the project financing. This can be a significant proportion of the overall project cost, accounting for around 45% for an average wind farm.

Normally, wind resource is measured using large steel towers called met masts, which require a large capital investment ($14 million to $17 million) incurred at risk before a project gets the go-ahead adding significant upfront costs. The OWA project aims to test how accurately scanning LIDAR technology can measure wind resource for potential wind farm sites, which could deliver significant cost savings in the early stages of wind farm development, says Carbon Trust.

The units involved in the trial are the following:

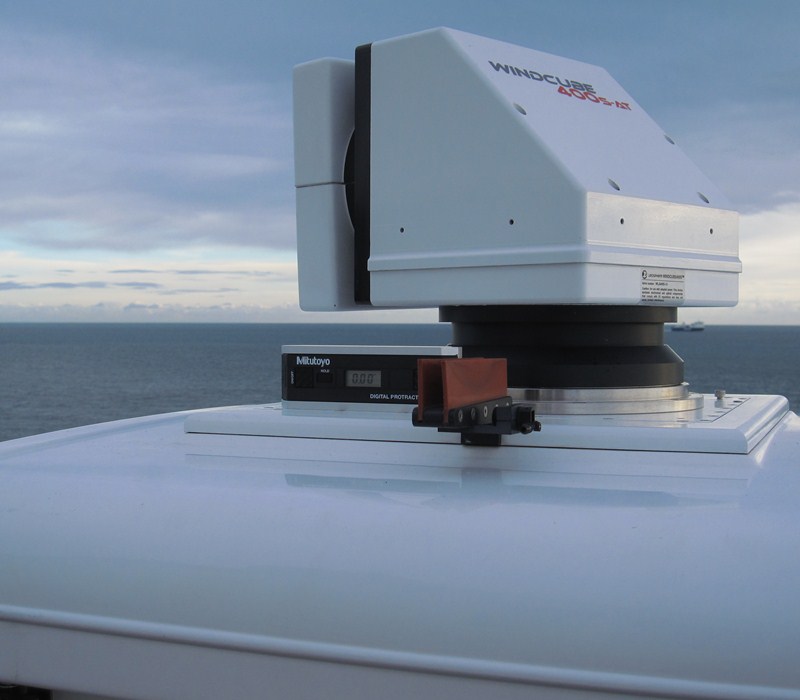

- Three Leosphere WINDCUBE vertical profiling LIDARs

- One Leosphere WINDCUBE 400S scanning LIDAR

- One Leosphere prototype scanning LIDAR

- Two Lockheed Martin WindTracer scanning LIDARs

“Project financing is a significant proportion of cost, so anything we can do to get a deeper understanding of yield will increase investor confidence and lower the cost of financing,” says Megan Smith, project manager of wakes research at the Carbon Trust.

“Scanning LIDAR has the potential to take our understanding to a completely new level. In information terms, it is the difference between taking a still photo compared to having a three-dimensional video with full sound,” Smith continues. “The need to test the sensitivity of the technology is the next frontier in getting industry acceptance.”