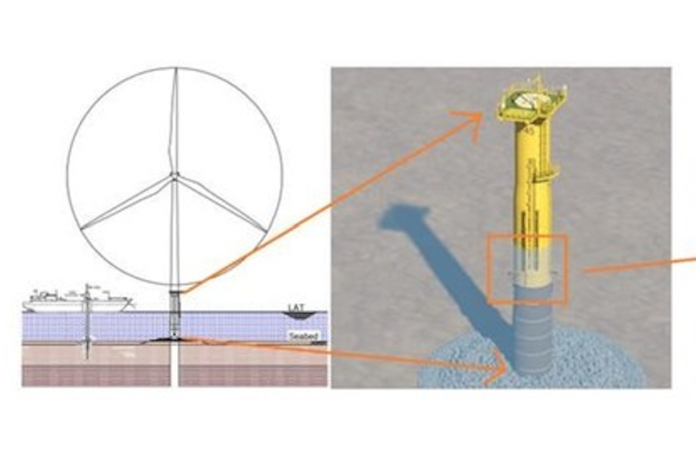

Van Oord, a Dutch maritime contracting company, says it is working with Ansys, a global company that specializes in engineering simulation, to speed environmental sustainability while expediting new product designs for the offshore wind turbine industry. Ansys is aiding Van Oord engineers in their development of wind turbine foundations, helping them increase product quality and deliver new innovations efficiently to market.

Designing wind turbine foundations typically requires Van Oord engineers to invest considerable time developing numerous complex, dynamic analysis finite element models. To accelerate and optimize the simulation process, Van Oord’s engineering team worked with Ansys channel partner Infinite Simulation Systems B.V. to harness Ansys Mechanical and Ansys Cloud, which spurred design optimization, significantly shortened product development timelines and boosted the efficiency of next-gen offshore wind turbines.

“Van Oord engineers employ Ansys Cloud to spur new product innovation and solve the ever-growing number of mechanical models which may feature over 5.5 million degrees of freedom, 1.8 million nodes and 550,000 elements,” says Ralph Luiken, engineering specialist at Van Oord. “Historically, these massive models each required 150 hours to run. With Ansys Cloud, our team has reduced run times to less than 24 hours per simulation. This has substantially sped up product development, enabled us to expediate our negotiations with foundation steel suppliers and expedited delivery to our global customers.”

Leveraging Mechanical and Ansys Cloud allows Van Oord engineers to run five times more design iterations on Cloud to predict the performance of advanced wind turbine foundations and enhance the fabrication processes while reducing project risks and speeding supply chain negotiations. As a result, simulations that required a week to run on multiple costly workstations now run overnight, delivering an improvement in time savings while greatly decreasing risk of production delay.