Getting the most of evolving opportunity in the wind power market requires reliable operation and dependability in every component of a turbine, and it’s especially critical in a turbine’s main shaft. Premature damage is costly, with main shaft bearing disassembly and replacement requiring blade removal, the rental of expensive and specialized equipment, and other operational pains.

That’s why selecting an optimized main shaft bearing lubricating grease is important for overall turbine reliability in a variety of challenging conditions. The right grease can help prevent premature bearing damage in turbines fleetwide; seal out environmental contaminants; prevent wear and micropitting; reduce friction during operation; provide rust and corrosion protection; and contribute to overall extended bearing life.

The Timken Co. recently performed numerous tests on commercial wind greases to identify and evaluate the critical attributes of an optimized lubricating grease for enhanced wind turbine performance. This article outlines our findings.

Operational challenges in wind power

Today’s powerful wind turbines operate under a variety of challenging conditions, including as follows:

- Slow operating speeds: Lubricating grease must provide sufficient separation between the bearing rollers and raceways. For that to occur, the grease must form adequate film thickness throughout operation. Film thickness formation, however, is inhibited by slow speed operation. Insufficient film thickness can lead to micropitting on the bearing surface.

- Vibration: Vibration in wind turbines is another challenging condition; even if the blades on a turbine are visibly still, the application can still experience “micromovements,” or fretting, impacting the bearing raceway. This contributes to wear and corrosion, but optimized grease can offer adequate protection.

- Variable and shock loads: Wind speed, direction and turbulence change constantly, and turbines must contend with these irregularities. Changing wind speeds and loads can lead to quick increases in rotation. Conversely, turbine operators must sometimes apply the brakes, leading to a sudden stoppage. All put stress on the bearing and lubricating grease.

Climates also impact performance. Lower temperatures cause thickening; a lubricant that pours like water in regular temperatures can become thicker than molasses when temperatures go below freezing. Greases must also account for environmental factors, like water ingress from humidity and precipitation. In offshore applications, salty air and water can interfere with film thickness.

An optimized grease may also offer extended regreasing intervals, helping operators minimize maintenance. Most turbines are manually regreased every six months, though some utilize automatic lubricating systems. In either case, extended performance is desirable.

Defining optimized performance

The individual properties of lubricating greases vary significantly, and through technical engineering evaluation and testing, we sought to understand the impact of those properties on main shaft bearing performance.

We tested 14 individual greases overall. The following key performance characteristics were identified and tested under numerous industry-standard testing methods:

- Film formation

- Fretting wear/corrosion prevention

- EP/AW performance

- Oil release

- Structural stability

- High-temperature performance

- Low-temperature torque

- Grease mobility and pumpability

- Water resistance

- Rust protection

These tests provided information beyond what is offered on product data sheets. Beyond these performance criteria, we evaluated seven greases for additional attributes.

Film thickness testing: A PCS-EHD2 testing rig evaluated additive technology used by lubricating grease suppliers. Typically, base-oil viscosity is used to calculate the film thickness, a key parameter affecting the formation of micropitting damage. Additives like viscosity index improvers may help increase film thickness at varying operating speeds and temperatures, helping to prolong bearing life.

We demonstrated that operating speed and temperature influence film thickness and formation under constant loading conditions. Testing showed film thickness was reduced at heightened temperatures but increased at higher operating speeds. Throughout various temperature and speed conditions, it held true that higher base-oil viscosity resulted in higher film thickness during operation.

This test also helped compare changes in film thickness for new and used (worked) greases. Standard testing evaluates new grease performance; we sought to better understand performance in used grease. To simulate shearing over time, the grease was worked per ASTM D1831 for 500,000 revolutions. Testing revealed that grease film thickness was similar for fresh and worked greases.

Traction testing: To further investigate optimized performance, testing generated Stribeck curves to evaluate friction/traction coefficients. Using the WAM6 test rig, greases were evaluated at various slide-to-roll ratios, speeds and temperatures.

It’s important to evaluate the grease performance regardless of the bearing type (tapered, spherical or cylindrical bearing). Micropitting is influenced by sliding, necessitating testing under a wide range of dynamic conditions. Sliding has a significant impact on operational friction characteristics, and bearing design itself plays a significant role here. Traditionally, wind turbines have used spherical bearings for the main shaft. Spherical roller bearings inherently have sliding, called Heathcote slip, on the roller-race contact, whereas tapered roller bearings are designed with true-rolling motion to eliminate sliding. Where sliding increases, so too does friction, necessitating a grease choice that can effectively mitigate the performance-compromising effects of increased friction.

When it came to speed and temperature testing, results generally followed expectation: Higher temperatures reduced friction/traction coefficients. This was generally dependent on base-oil type (e.g., mineral or synthetic) used in grease formulation; greases with synthetic base-oils had lower traction coefficients than greases with mineral or semisynthetic base-oils.

Temperature, torque and grease migration testing: Using a lubricant evaluation machine, we evaluated operating temperature, torque, and grease migration and distribution throughout the bearing.

Grease should remain on the bearing surfaces to ensure adequate film formation and surface separation throughout operation. Proper grease distribution permits longer regreasing intervals and helps reduce wear through effective film formation and part separation.

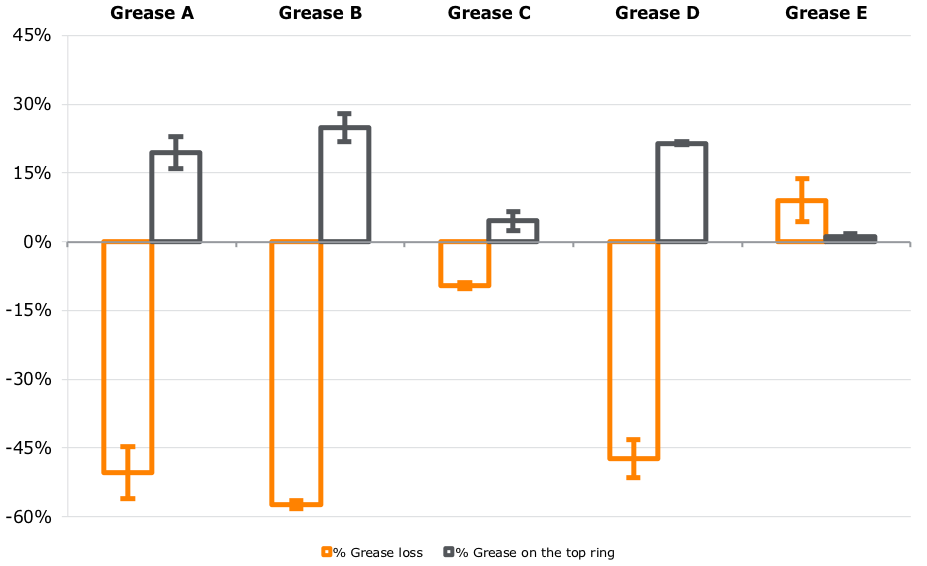

Testing results varied. As seen in the figure above, greases A, B and D (higher-viscosity greases) showed higher grease loss after testing, and a residual oil film remained on the rollers and raceway. Comparatively, greases C and E (lower-viscosity greases) demonstrated better performance, with minimal grease loss and plenty of grease and oil remaining on the rollers. Worked grease represented no significant change in grease migration behavior.

Concerning torque and temperature, greases A, C and E demonstrated lower bearing temperature, while high bearing torques were observed for greases B and D. Grease C demonstrated the most desirable overall performance here, with low grease loss and low temperature and torque.

Conclusions

We based final conclusions on film thickness, grease traction, bearing torque, operating temperature and grease migration. The winner? Grease A, a formulated high-viscosity grease with a synthetic base-oil, which demonstrated the most balanced performance overall.

However, grease performance is dependent on the application conditions. Where high-viscosity greases can become too thick in colder climates, for instance, a lower-viscosity grease or higher-viscosity index grease is more suited, as it will yield lower viscosity at low temperatures and thus will allow better grease migration.

Turbine manufacturers and operators must be diligent in grease selection and should seek suppliers with knowledge and expertise in all areas of grease performance in a variety of applications. Lubrication technology is improving all the time, and a grease that provides ideal performance across all critical areas – in all climates – is possible. And as wind power ramps up across the globe, optimized performance and reliability depend on it.

Douglas Lucas is an advanced engineering technologist and Kuldeep Mistry is a principal product development engineer at The Timken Co., an Ohio-based manufacturer of bearings and mechanical power transmission products. They can be reached at doug.lucas@timken.com and kuldeep.mistry@timken.com.

Photo and chart courtesy of The Timken Co.