Engineers at Iowa State University are studying the icing of wind turbine blades in an effort to improve power production of wind energy in the wintertime.

A three-year, $303,587 grant from the Iowa Energy Center will support the project, conducted using the university’s Icing Research Tunnel. The tunnel can produce temperatures down to -13 degrees F and airflow speeds up to 100 meters per second. In addition, the airflow carries water droplets from 10 to 100 millionths of a meter in diameter. A recent upgrade will also allow researchers to produce ice crystals.

The research group is led by Iowa State’s Hui Hu, a Martin C. Jischke Professor in Aerospace Engineering at the university.

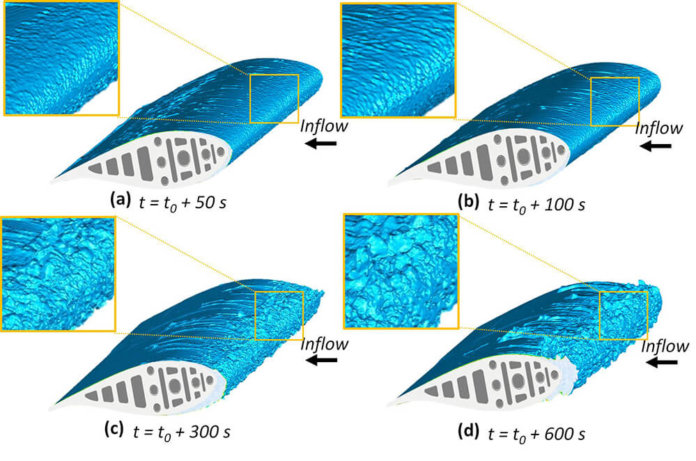

Using the research tunnel, Hu has produced 3D printouts of icy airplane wings, wind turbine blades and power cables. Where there were supposed to be smooth leading edges and curved and cambered surfaces engineered to create lift or spin with the wind, there were warts of bumpy and coarse ice building up just off the leading edges and trailing over the tops and bottoms of the airfoils.

He also had models of different kinds of ice: glaze ice (formed under relatively warm and wet conditions, such as freezing rain) and rime ice (formed under relatively cold and dry conditions from airborne, supercooled water droplets).

“This kind of quantitative information was not available before,” says Hu. “We’ve learned that very small surface modifications with ice-phobic coatings can change icing physics dramatically.”

In his latest project, Hu will specifically take a closer look at ice formation on wind turbine blades – and how to prevent or delay ice from forming. That study could make a difference on Iowans’ utility bills, says Iowa State.

Hu’s study team includes Linyue Gao, a postdoctoral research associate at the University of Minnesota and former Iowa State doctoral student, plus Haiyang Hu and Ramsankar Veerakumar, doctoral students in aerospace engineering at Iowa State.

The university notes that lab conditions do not always reflect conditions in the field. In turn, when Hu couldn’t get permission to measure ice on Iowa wind turbines, he used connections in his native China that allowed a student to take drone footage of icy turbines along a mountain ridge.

The images and resulting measurements helped quantify how icing on turbine blades can reduce power production.

“Iowa winters are supposed to be the best season for wind energy harvesting due to the abundant wind resources and increased air density with decreasing temperature,” Hu and his research group wrote in a description of their project. “However, ice accretion on turbine blades was found to decrease a turbine’s power production significantly (i.e., up to 50 percent reduction at critical icing sites).”

Current technology takes some of the power produced by turbines to heat the massive surface of turbine blades. However, that consumes a lot of energy, the researchers say.

Hu’s group will study a hybrid anti-/de-icing strategy: Minimized heating only at small, critical parts of the blades, such as leading edges, and applying durable, ice-phobic coatings along the rest of the blades.

“While Iowa ratepayers usually pay higher electricity bills in winter,” the researchers wrote, “this project will lead to a novel anti-/de-icing strategy to improve power production of Iowa wind turbines in winter, thus lowering the electricity bills of Iowa ratepayers.”