Pile driving is a major task in the construction of offshore wind farms. It is also one of the higher-risk activities due to the many unknowns.

These monopile or jacket foundations are also installed in challenging construction environments where the reliability of the test measurements is essential. Timeliness and flawless installation are directly linked to significant economic savings.

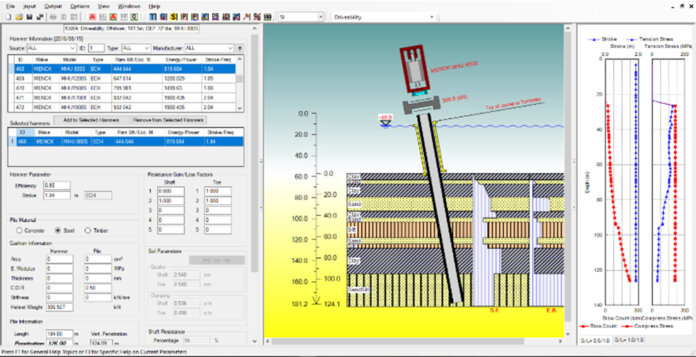

Our firm has helped achieve successful pile installation for offshore platforms in fields throughout the world. We generally start with a pile drivability study, using the wave equation analysis of piles software program GRLWEAP.

GRLWEAP’s Offshore Wave Version is particularly well-suited to analyze complex situations encountered in offshore pile driving. It simulates the motion and forces in a foundation pile when driven by an impact or vibratory hammer to help improve the accuracy of predicted stresses, bearing capacities, blow counts and installation time.

A drivability study is also helpful to select the installation equipment needed to achieve the required pile penetration depth to satisfy lateral loading demand.

Once pile driving starts, we perform dynamic pile monitoring by attaching strain transducers and accelerometers near the pile head. From these measurements, the pile driving stresses, performance of the driving system (energy transfer) and bearing capacity can be evaluated. These are important concerns in offshore pile installations.

Immediately following pile driving, we use the collected dynamic measurements to further evaluate the pile capacity using the CAPWAP software. CAPWAP provides an assessment of the shaft and toe resistance at the time of testing, which can be compared to the foundation design assumptions.

To minimize offshore operation downtime, we provide backup testing equipment and personnel to the site.

Alex Ryberg, P.E., is vice president and Pennsylvania branch manager for GRL Engineers Inc. He can be reached at aryberg@grlengineers.com.