GE, Fraunhofer IGCV and voxeljet AG have formed a research partnership to develop the world’s largest 3D printer for offshore wind applications in order to streamline the production of key components of GE’s Haliade-X offshore wind turbine.

The Advance Casting Cell (ACC) 3D printer under development will benefit from financial support from the German Federal Ministry for Economic Affairs and Energy and will be capable of printing molds to cast components for the nacelle of the GE Haliade-X – which that can each weigh more than 60 metric tons – reducing the time it takes to produce this pattern and mold from 10 weeks or more to just two weeks.

In addition, the use of the 3D printer is expected to reduce the product’s carbon footprint by eliminating the need to transport the large parts from a central manufacturing location.

The partners expect to launch the project during the third quarter of 2021, with initial printer trials starting during the first quarter of 2022.

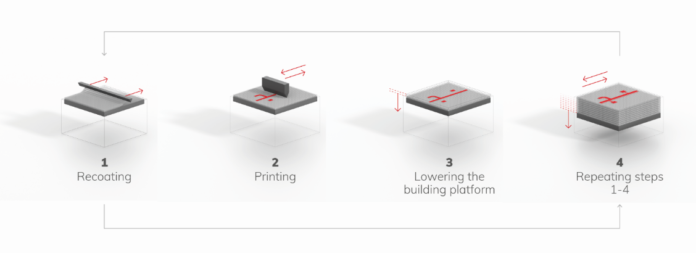

The project involves the development of a new, large format 3D printer capable of producing sand molds for casting the highly complex metal parts of different shapes and sizes that make up an offshore wind turbine nacelle. The modular 3D printing process, which is based on voxeljet’s core “Binder-Jetting” technology, can be configured to print molds for castings up to 9.5 meters in diameter and 60-plus tons in weight, dimensions.

The Fraunhofer Institute for Casting, Composite and Processing Technology IGCV is responsible for casting and materials technology issues, as well as digital process monitoring.

“The test mold we printed for GE in 2019 consisted of dozens of individual parts,” explains Christian Traeger of voxeljet. “With the ACC, we aim to print a significantly reduced number of parts for the full set. Added to that, the mold can be optimized in terms of functionality and material consumption. This optimization makes completely new casting designs possible that can further enhance the efficiency of the turbines.”